For the food industry

For the cosmetics industry

For the pharmaceutical industry

PacDrive 3 servo drive systems

PacDrive 3 is the latest in a series of servo drive systems, the successor to ELAU's PacDrive M series.

The PacDrive family of servo drives has been a leader in both the German and global market for packaging machines and systems for more than 20 years. Users value these solutions because machines equipped with them guarantee performance

at the highest level.

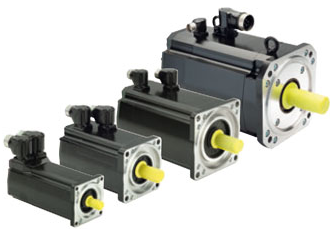

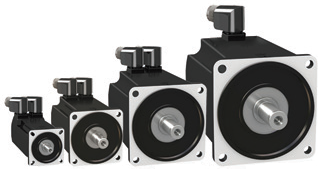

Solutions in the PacDrive 3 series

adaptable servo drive design

single and dual servo drives

single power supply and power rail

automatic device detection

Plug&Play architecture

wide range of motors

Benefits

space reduction in the control cabinet

energy efficiency - braking energy recovery

reduced deployment time

fast replacement

reduction of system costs

Details

PacDrive 3 servo drives

|  |  | |

|---|---|---|---|

| Series | |||

| Description | |||

| Recommended application | |||

| Compatible controllers | |||

| Compatible motors | |||

| Dual servo drive availability | |||

| Nominal power | |||

| Continuous current | |||

| Peak current | |||

| Brake energy recovery | |||

| Communication protocol with other devices | |||

| Available versions with security features |

PacDrive 3 servomotors

|  |  | |

|---|---|---|---|

| Series | |||

| Description | |||

| Compatibile servodrives | Lexium 62 | Lexium 62 | Lexium 62 |

| Nominal power | |||

| Rated torque | |||

| Peak torque | |||

| RPM | |||

| Flange sizes | |||

| IP degree of protection (shaft / housing) | IP65 / IP65 lub IP65 / IP67 | IP67 / IP67 | |

| Optional brake | |||

| Shaft end | |||

| Cable connectors | |||

| Encoder type | High-resolution, single- or multi-turn | ||

| Electronic nameplate |

Motion controllers

Logic Motion Controllers (LMCs) - the eleven controllers of the PacDrive 3 family designed to manage applications requiring the highest performance and control of synchronized motion of up to 130 axes simultaneously. Such extensive control of servo systems is ensured by the use of Intel processors with processor clock rates up to 2.2 GHz.

Details

LMC motion controller with integrated PLC - one control device for the entire machine

![]() Advanced diagnostic functions: built-in oscilloscope in the control program, extensive event logger,

Advanced diagnostic functions: built-in oscilloscope in the control program, extensive event logger,

![]() Multiplicity of communication protocols

Multiplicity of communication protocols

![]() Easy service: quick replacement of the device in case of failure, no need for reprogramming (only flash memory card reloading required)

Easy service: quick replacement of the device in case of failure, no need for reprogramming (only flash memory card reloading required)

![]() PC-free operation: integrated text display in five languages for system and diagnostic messages

PC-free operation: integrated text display in five languages for system and diagnostic messages

![]() Simplified programming: a prepared project template (so-called Template) with a large number of ready-made function blocks, the possibility to create your own libraries

Simplified programming: a prepared project template (so-called Template) with a large number of ready-made function blocks, the possibility to create your own libraries

LMC series controllers are equipped with a SERCOS communication bus to ensure proper communication speed, so we can provide a network scan time of 1-4ms. SERCOS III protocol based on the physical layer of Ethernet allows us to communicate all system components such as controllers, servo drives, IO systems, and safety systems ensuring full control of the machine.

Besides the SERCOS bus, PacDrive LMC motion controllers can support

| IT protocols:

| serial communication:

|

There are also optional expansion cards available for all controllers to use additional communication interfaces such as EtherNet/IP.

In order to control motion over individual axes of the real system, the control program uploaded to the controller can have up to 4096 electronic CAM motion cams that can be switched between each other during motion.

SoMachine Motion software is used to build the control program for LMC controllers. It allows you to create a single control program for system operation logic and axis motion profiles. As standard, it includes a number of libraries with ready-made function blocks for the most common servo applications. Dedicated diagnostic software is available for quick diagnostics of the controllers.

Need more technical information?

Check out motor dimensions, connector descriptions, and more in our technical guide!

Modern and efficient systems for packaging machines

With PacDrive 3 solutions you can achieve shorter time-to-market and reduced unit cost for your products. For more than 20 years, the PacDrive family of servo drives has been a leader in both the German and global packaging system machine market. Customers value these solutions because machines equipped with them guarantee performance at the highest level.

Mateusz Biega Packaging Process Automation Specialist

Benefits

Full integration with MES/SCADA systems and Flexibility for scheduling machine operators

Visualization of KPIs for production staff

Ensuring production continuity

Energy efficiency of machines

Reduction of system costs,

Service warehouse and downtime

Features

PackML standard compatible

Simple and fast data collection from the machine

Efficient diagnostic tools and fast replacement

in case of failure

Braking energy recovery

One control platform for the machine/line

Production

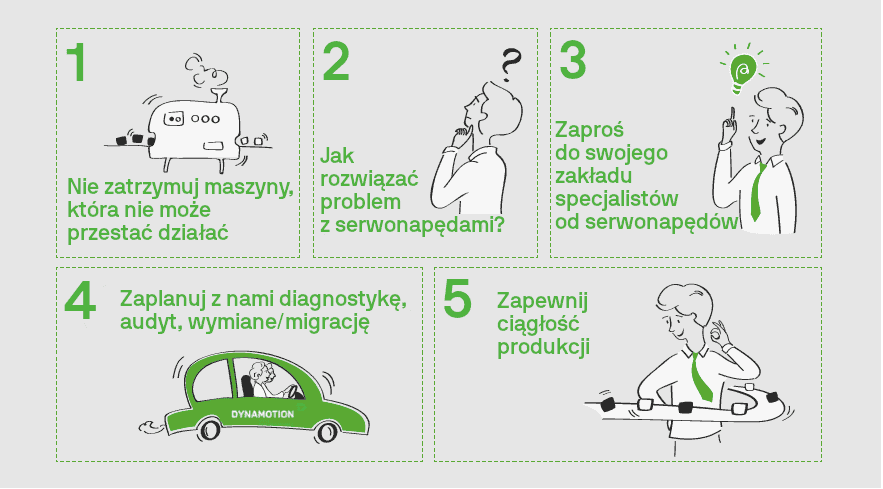

ELAU servo systems - PacDirve M withdrawn from sale as of 31/12/2018.

Check out the options for migrating systems to the PacDrive 3 series.

How do we operate?

We perform on-the-move diagnostics, systems audits, consultations, and on-site training. Preventive maintenance PacDrive conducted by certified DYNAMOTION engineers supports the elimination of failures and downtime and helps expand the knowledge of servo systems.

Grzegorz Król Technical Support Specialist